By the turn of the century, print shops were augmenting their product mix with new methods of creating signage, which, in the past, required additional materials and steps to produce. The advent of direct to substrate printing simplified the process, shortened production time, reduced costs and created a boon for retail, advertising, real estate and display.

Before Direct to Substrate Printing

Before direct to substrate printing, or board printing, an image would be created – a print, label or decal, and applied to a substrate. Now, direct to board printing utilizes a large flatbed UV substrate printer. This printer is capable of applying ink containing acrylic monomers that can then be bonded together to almost any flat substrate. Once the monomers are applied, the substrate is passed through a strong UV light for curing. The curing process binds together the monomers. This process forms the desired image and adheres the impression to the substrate material.

This new sign printing printing process can be used to print directly onto durable, long-lasting surfaces such as aluminum/metal, acrylic, Ultra Board, Gator Board, Coroplast, and PVC Sintra. More flexible materials can be printed as well, including corrugated boxes, magnets, and Styrene. In all instances, graphics can be created that are large and detailed enough to pass the rigid standards required by court rooms for admissible evidence. They can also be used for indoor our outdoor signage. The advantage for outdoor signs is that they provide weather resistance, durability, flexibility and reusability.

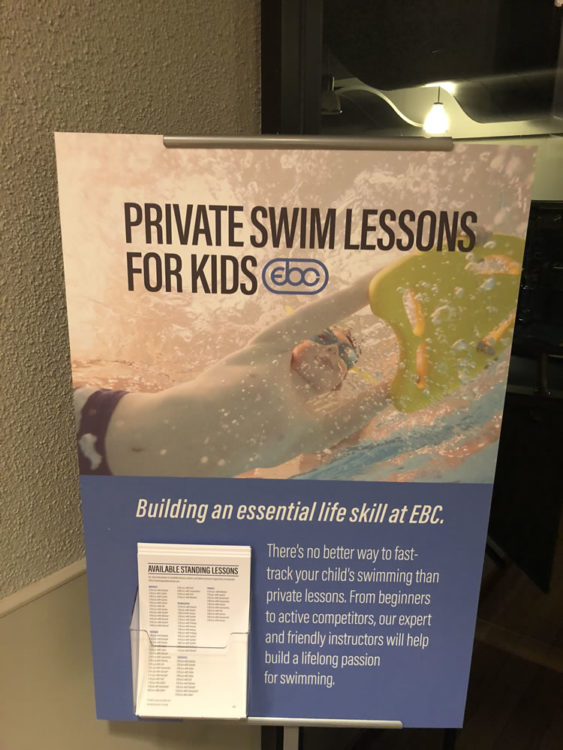

DiBond and Sintra PVC are two of the substrates Gamma frequently prints to. With the advantage of Gamma’s two board printers curing the inks directly onto the substrates’ surfaces, providing a durable, fade and scratch resistant finish, two of Gamma’s clients – one, a sports and athletic facility, the other, a well known Chicago artist, look to Gamma to provide graphic solutions.

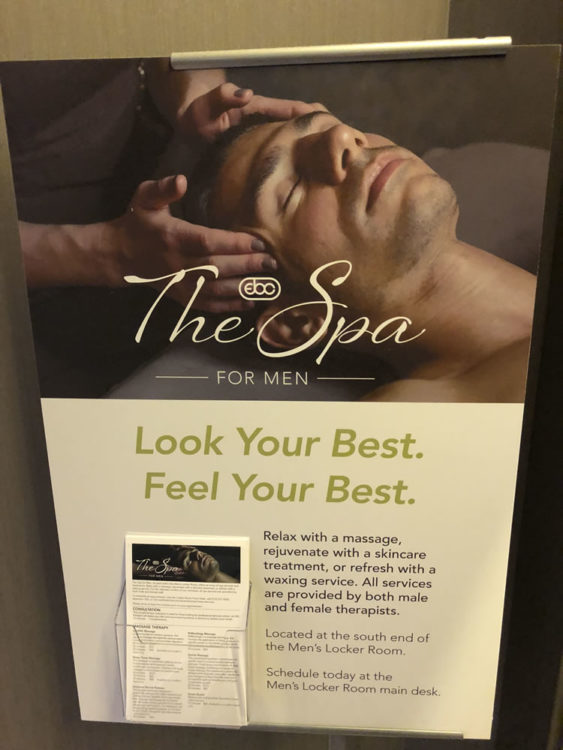

For the East Bank Club, Chicago, the need to inform members of new equipment and exercise programs, modernization and construction undertakings, and upcoming events all demand rigid, durable signs. For years, Gamma’s flatbed printing has supported East Bank’s signage requirements.

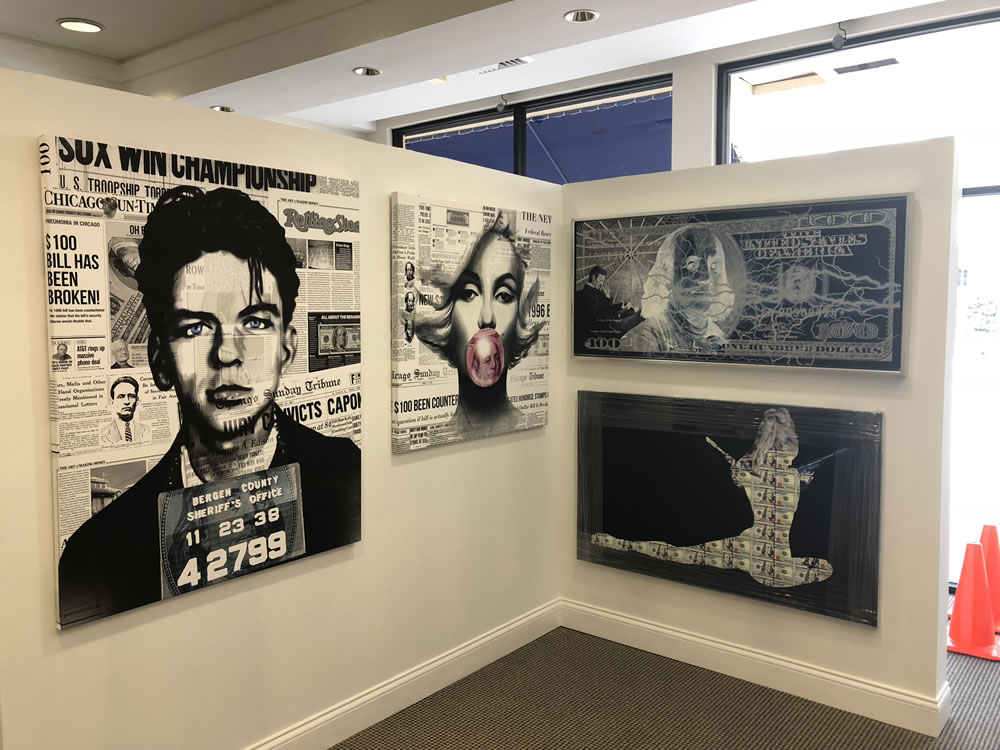

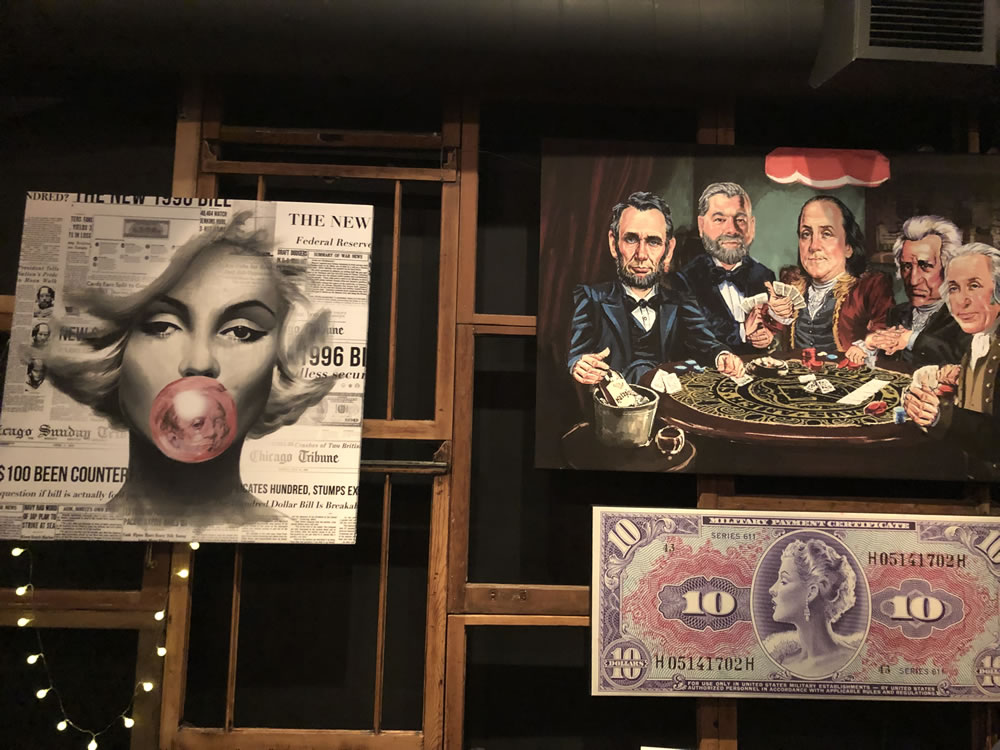

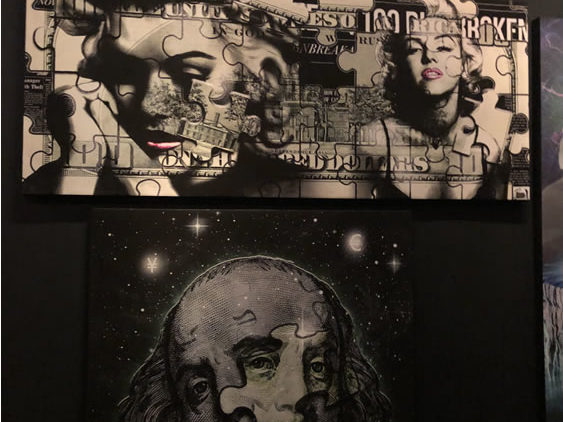

Artist Arthur Williams looks to Gamma to print his fine art images with a sleek, contemporary look. Printing to DiBond material provides the sharp detail, rich saturation and permanence that appeals to art buyers.

Arthur Williams Fine Art that Gamma Printed

.

Direct to Substrate Printing Equipment

Gamma’s Acuity Advance HS-X2 is considered the finest of the current generation of newly improved UV-LED printers. With UV curable ink and its ultraviolet LED curing lamp, the Acuity cures and encapsulates the ink making it instantly dry and abrasion resistant. There is no need to let the ink out-gas. For outdoor use, UV inks help to retard damage due to the sun and harsh weather conditions, enabling art to retain its color for a long time.

Our newest printer, the HP Latex R1000 prints well to coated and uncoated materials, from papers and vinyls to backlit films and textiles. Its ability to print to materials that are flexible and stretch – vinyl film for auto wraps and fabric banners for display, for example, is unsurpassed. Projects can be turned around quickly, as the ink is dry as it comes off the printer. The output can be rolled, cut or used immediately. Equally important to the quality of printing and speed of production is the environmental impact of the HP’s inks: they are eco-friendly both in terms of ink disposal and incineration of used prints.

Direct to Substrate Printing Materials

Sintra has been the industry’s leading PVC board for more than twenty years. It is lightweight, yet rigid and can be cut, shaped and formed to create unique designs. Durable Sintra cuts cleanly with smooth edges. It’s dense cell structure offers greater rigidity than others of its type; the more porous PVC boards can be flimsy; Sintra’s structure makes it superior, especially for outdoor signage. Moreover, it’s superior print quality is attributable to its smooth and very dense surface. It is not likely to dent as do other PVC boards.

DiBond is an aluminum composite material. It is one of the most robust, lightweight materials on the market. It is comprised of two prepainted sheets of .012 aluminum with a solid polyethylene core. It is this black polyethylene core which provides stability and optimizes long-term performance. In fact, of all the substrates on the market, DiBond’s particularly high corrosion-resistance makes it the most recommended for long lasting outdoor signage. As for image quality, DiDond’s absolute flatness ensures optimum printability, including the reproduction of fine lines. Finally, as for projects, DiBond enables full machinability, permitting precise cutting into sizes and shapes.

Gamma offers a variety of portable display stands that can be used in multiple environments. These

Gamma offers a variety of portable display stands that can be used in multiple environments. These